Description

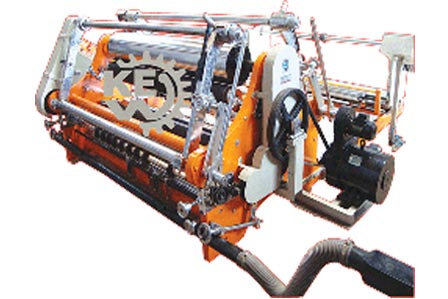

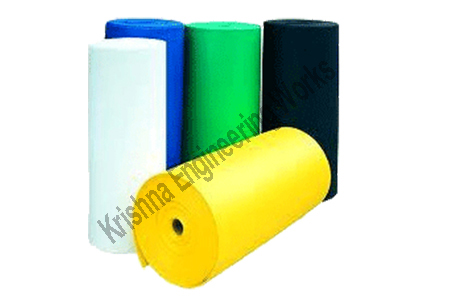

Krishna Engineering Works Duplex Shaft Slitter Rewinder Machine Manufacturer, Exporter, and Supplier. It incorporates a range of best design features, including the cantilever type, ensuring the highest possible quality for the final split roll. Measures independent rewind stress control diameters by non-contact ultrasonic techniques and by unique core locks for gaps. The design of this machine includes three motor control systems and unwinds the pneumatic brake with load cell feed brake digital edge/line guiding to achieve high-speed correction. Also, we manufacture all kinds of industrial rubber rollers for slitter rewinder machine.

We have been in the global market for the last 25 years: Nigeria, Ghana, Congo, Kenya, Zambia, Sri Lanka, Bangladesh, Malaysia, Pakistan, Nepal, Russia, Thailand, Indonesia, Brazil, Colombia, Venezuela, Argentina, Mexico, Canada, etc. And we are successfully manufacturing, exporting, and supplying all types of Duplex Slitter Rewinder Machine from Ahmedabad, Gujarat, India, including more than 1400 installations all over India and abroad including Saudi Arabia, UAE, Dubai, Sharjah, and South Africa. We are also the winner of 3 times national awards and 2 times international awards for quality products.

Standard Features

Duplex Slitter Rewinder

Non-woven fabric, BOPP film, plastic, paper, flexible packaging, PVC, aluminum foil, LDPE film, stretch film, BOPP tape, OPP, MET PET, PET film, OPA, paper board, adhesive, etc. This machine is used for the work of film ribbon, ice cream cup paper, textile cloth, nylon fabric, micro tape, coated paper, fax roll, laminated film, cling film, duct tape, mask tape, rubber, tarpaulin, tube, etc. We are a manufacturer, exporter, and supplier of Duplex Slitter Rewinder Machine.

- UNWIND STATION:

- One Mechanical / Automatic Web guiding system

- One Mechanical / Automatic Brake

- REWIND STATION:

- Type of Rewinding Duplex differential

- Rewind Control through, two Clutch assemblies mechanical

- Individual Slip Ring arrangement as per require cut

- Razor Cutting (Standard) (Circular Knife – Optional)

- NIP UNIT:

- With one full-width Capacity, hard chrome plated steel roller of 150mm

- Dia. and one 150mm dia. synthetic rubber roll

- One Pressure adjusting device Mechanical for Nip Roller Pneumatic (Optional)

- CONTROL PANEL:

- Variable A.C. drive with Blower & Web Guide Controls

- SALIENT FEATURES OF DUPLEX SLITTER REWINDER MACHINE:

- The most versatile, the model provides a combination of Duplex Center cum Surface Rewind System

- Constantly flawless slit rolls by providing a center driver drum to maintain. The fixed minimum distance between slitting and rewind point

- Constant Line Speed causes constant tension rolls

- Two Rewinding Shafts carried on swinging arms are center driven through an adjustable slipping clutch

- Counter Balance System to adjust the pressure between rewind reels and center drum

- Suitable for off caliper / slippery/stretchy material

- In separate cases, the rewinding shaft may be provided with the provision of individual separate slip assemblies for each slit reel.

- Slitting methods as per customer requirements like Scissor cut/crush cut (Circular knives) / Razor blade slitting system

- Side Frame Construction of Ribbed Anti Vibration C.I Body

- Rewind – Central Drum or Duplex Type

- Dynamically Balances drive rollers

- Trim Separation by Air Blower of 1.0 HP AC Motor

- Line Speed up to 100 – 200 meters/min. Depending on the thickness of the materials & operating conditions

- Customized Roll Handling System for Enhanced production & Ergonomic Safety

- AC/DC Drive system

- OPTIONAL ATTACHMENTS FOR DUPLEX SLITTING REWINDING MACHINE:

- Auto Tension Control System for Unwind Unit

- Digital Line Edge Guide System

- Web Edge Guide System (Hydraulic / Digital Ultrasonic)

- Pneumatic system for Arm / Clutch / Brake / Nip

- Air shaft for Unwind Station & Rewind Station

- Safety chucks at Unwinder Station

- Bow rollers or Banana Roller for Wrinkle Free Working

- Four motors synchronized drive

Our slitting machine is the ultimate Duplex Slitter Rewinder Machine for its precise slitting and rewinding qualities. It ensures the perfect slitting of rolls with flawless results and constant line speed. It is available in an adaptable model to suit your needs. Our duplex slitter rewinder machine is available in rewinder, duplex surface slitter, rewinder, and differential Cantilever slitter and rewinder. Our slitting rewinding machine is known for its high-speed accurate slitting and low vibration.

The KEW slitter rewinder machine ensures the complete slitting of rolls with consistent flawless quality and consistent line speed. It is available in an adaptable model to suit your needs.

Technical Specification

| Technical Specification of Duplex Slitter Rewinder Machine: |

| Web width | : | 400 to 5000 mm |

| Maximum Diameter Of Stock Roll | : | 600 – 1000 mm (1200 mm – 1400 mm Optional for Heavy Duty Model) |

| Minimum Slit Width | : | 15 mm |

| Maximum Diameter Of Finished Roll | : | 400 to 600 / 1000 mm / 1200 mm – 1400 mm (Optional for Heavy Duty) |

| Operating Speed | : | 3-15 HP at 415 V, 3 Phase , 50 cycles A.C. Supply |